Fabric embossing

Introduction

Pattern embossing service is similar to pleating - in this case we also change the structure of the material as a result of high temperature and pressure. Unlike pleating or creasing services, in embossing, there are no folds created on the material, but we imprint a previously prepared pattern on its surface. We offer two types of embossing:

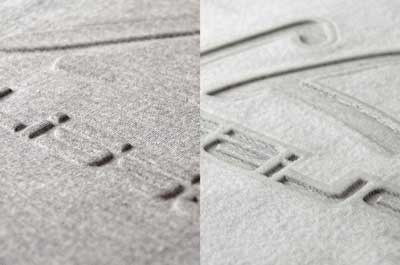

Standard embossing (debossing)

In this type of embossing, the pattern (in the form of a mould made in our company) is first heated to the appropriate temperature and then pressed onto the material using a precisely selected pressure force. As a result of the process, a debossed image of the pattern is created on the material, and thanks to the temperature and pressure, the deformation of the fibers is permanent. We use the structure of the material and its thickness - that is why the embossing is best visible on materials with a higher material weight / volume and/or a clear structure (e.g. polyester knits, fleece materials, divers). The embossing is durable and resistant to washing. The standard size of the mould in debossing is 60 cm x 70 cm (width x height) and most of the moulds from our pattern database have this size. It is also possible to order your own mould with dimensions of up to 70 cm x 100 cm (width x height)

Application: Debossing is possible only on polyester based materials.

3D embossing

Unlike the previous embossing variant, in this service we use a specially prepared set of matrix and matrices. Their use allows us to shape the material according to the customer's wishes.

The maximum embossing size is about 4 dm²

Application: 3d embossing is possible on:

- PA, PES based materials (np. scuba, softshell)

- cotton based material - by utilizing a special polymer layer on the back side

If you would like to try embossing on a different material, please send us a material sample for a material test.

Thanks to our modern machinery, we are now able to offer you 3D embossing on ready-made (sewn) elements, such as T-shirts or sweatshirts. This shortens the production process, and at the same time, it is possible to reduce costs by using ready-made blanks.

Technology

The machines we use ensure an even distribution of force on the surface of the entire embossing, thanks to which the embossing is clear and its depth is the same throughout the entire area. We ensure high accuracy of the embossing position on the patterns, we offer the possibility of applying the embossing in a place of the pattern chosen by the customer. We also cooperate with clients on non-standard orders, such as glued embossings - we have many years of experience, which allows us to propose tailored solutions regardless of their degree of complexity.

Designs

Currently, our database of ready-made patterns contains over 150 different patterns of deep embossing - both large patterns, borders, and small, individual applications. In the case of 3D embossing, 100% of our projects are custom-made patterns, using e.g. a brand logo or a collection slogan, therefore we do not keep a catalog of patterns for these types of embossing. We also offer the possibility of making a matrix based on a design provided by you, providing our technical advice at the design stage.

MOQ

In all types of embossing we offer, we have separated the mould preparation and embossing stages. Thanks to this, we have eliminated the production minimum - it is you who decides exactly how many pieces you want to make in a given order for given design.

Where to start

The embossing effect depends largely on the type of material - not only its composition, but also its structure and color. Before you start designing your own design, we invite you to send us the material so that we can test the selected embossing using our test moulds.

Custom embossing

In addition to the above-mentioned service options, we also carry out custom orders. If you want to make a different type of embossing, try to make it on a different material (including atypical ones), combine different services or try to recreate embossing based on a photo or model - please contact us.