Machine pleating

Introduction

Machine pleating is a process in which the material enters a special machine, the machine folds the material (along with protective papers) in the desired way using special knives, applies temperature and pressure, and cools the material after a while. As a result, the folding pattern created by the knives is fixed on the material and remains unchanged after the material is removed from the papers. Each fold is commonly referred to as a pleat, hence the name of the process. There are several basic types of machine pleating: straight pleats, fancy pleats (Harlequin, herringbone pattern), accordion pleats.

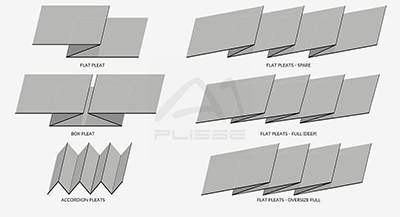

Straight pleats

One of the most popular types of machine pleating. It is most often found in the form of a repeating pleat of a fixed length, but there is also the possibility of introducing greater finesse into the pleats created. Depending on the set pattern, the pleats can change their length during the operation of the machine according to the program, insert spaces or box pleats, while maintaining an ideal repeatability of the pleats even in the case of very large batches of material. Another interesting solution is the possibility to make "shot" inserts, e.g. in the middle of the blouse, also according to the selected pattern. In this way it is possible to insert a selected number of pleats on a selected section of material.

Straight pleats with fade effect

A variant of straight pleating, where pleats are created only on a fragment of the material, leaving about 30 cm from the edge unpleated. Thanks to this, the material has a slightly larger volume at this edge and drapes more nicely. This type of pleating is used, for example, in sleeves or short skirts.

Printing on pleated material

Sublimation printing on pleated materials. The elements obtained in this way are colored only on the surface of the visible fold, while the rest of the material remains unpainted. In combination with interesting patterns from our database, this allows for achieving amazing spatial effects.

Fancy pleats - Harlequin

This type of pleating is created by the work of a machine with a segmented knife. The division of the pleating knife into parts allows the machine to perform a different movement on selected parts of the material, thanks to which the machine can, for example, alternately create a pleat and a box pleat. Additionally, in harlequin pleating, a lateral movement of the knife is introduced, which causes a change in the position of the pleats and box pleats across the width of the material during machine operation. It is possible to set production parameters such as the size of the lateral movement, lateral movement settings and pleat height. The use of this technique is mainly for pleating material for small inserts, e.g. for hats, where we want to obtain a fairly geometrically complex pattern on a very small surface. It is possible to pleat material up to 150 cm wide, also slightly thicker knits. Similar patterns: herringbone, crushing, small straight pleats.

Fancy pleats - herringbone

This type of pleating is created by a machine with a special wavy knife. When the material passes through the machine, a pattern is created consisting of alternating lines, creating a characteristic "herringbone". It is possible to adjust the size of the pleat (how densely the lines are repeated). This technique is mainly used to pleat material for small inserts, e.g. for hats, where we want to obtain a fairly geometrically complex pattern on a very small surface. It is possible to pleat material up to 150 cm wide, also slightly thicker knits. Similar patterns: harlequin, crushing, small straight pleats.

Accordion pleats

Accordion pleating is a special type of machine pleating in which the material is arranged in a shape resembling an accordion, where the folds are made at equal intervals and the resulting pleats are not flat. We have designed and implemented special solutions that allow us to use this type of pleating only on a fragment of the material, part of the material, leaving the rest unpleated or, for example, with a previously straight pleat. In contrast to the 'straight pleat' pleat, this type of pleating, we have the possibility to add unpleated inserts up to up to 50 cm wide in the middle of the material (the sides of the material are (the sides of the material are pleated, the middle is not) or to create a combination of combination of pleated and unpleated fragments. It is possible to to pleat materials up to 150 cm wide, it is possible to set the height of the pleat in the range of 3-6 mm. Thanks to the use of special of special modules in the machine in this pattern, we also offer the possibility to two sizes of pleats side by side on one material - a double pleat (smaller) and double pleat (smaller) and single pleat (larger). The working of the modules for double pleats is about 25 cm.

Accordion pleats – large pleats

Using other machines, we are also able to make an accordion pleat (also called standing pleats) in a larger version. The large accordion pleat is visually very similar to the pleat found in sunray pleating, but here the pleat height is constant across the entire width of the material. In sunray pleating, the pleat is small at the undercut and increases towards the lower border of the cut.

Fancy pleats - ruffle

Another example of modular pleating, in which there is great freedom in shaping the created pattern. In ruffle pleating, the pattern is created by tiny sharp wheels (arranged at 1 cm intervals), which press the material in selected places. By turning on or off selected wheels, we can selectively pleat the material - e.g. 5 cm from the edge pleated, then 10 cm unpleated, the next 15 cm pleated and 10 cm unpleated. In ruffle pleating, the created pleating pattern is characterized by very high elasticity. It is possible to pleat materials up to 150 cm wide.

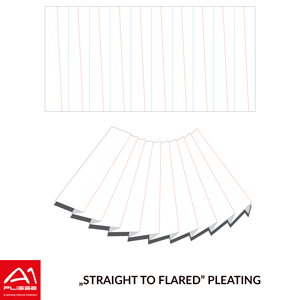

"Straight to flared" pleating

This type of pleating is available in both machine pleating (limited possibility of customization) and hand pleating (large possibility of customization). In "straight to flared" pleating we start with a rectangular pattern, but after pleating the pattern becomes slightly flared. This is due to the specific arrangement of knives in the pleating process, which "hide" the missing material by creating a non-parallel fold. The maximum width of the material in this type of pleating is 80 cm. The advantage of this type of pleating is obtaining a slight flaring of the skirt. As a result, the skirt emphasizes the female figure more, the pleats slightly wave and give the impression of greater softness of the material.

Custom pleating

In addition to the above-mentioned service options, we also carry out custom orders. If you want to make a different type of pleating, try to make it on a different material (including atypical ones), combine different services or try to recreate pleating based on a photo or model – please contact us.