Hand pleating

Introduction

In hand pleating, the key to success is creating a form that reproduces the desired type of pleating. In the pleating process, the material is placed between two halves of the form, and then the form is folded and exposed to high temperature and/or steam. The exact process is adjusted to each order and depends on many factors, including the type of material, its reaction to temperature, the shape of the form. Many years of experience in this field allow us to perfectly select the parameters and processes necessary to obtain the best effect both in visual aspect and durability.

Thanks to our own mould workshop we are able to meet any order, even the most unusual. In addition to popular sunray pleating models, we also offer more sophisticated patterns (sunray pleating with additional pleats, pleats with varying height, cloche type pleating with flat pleats, geometric patterns and sunray pleating with godets) - each with the possibility of adapting to the requirements of your production.

Sunray pleating

Sunray pleating is the most popular hand pleating type that we provide. There are three main types of sunray pleating:

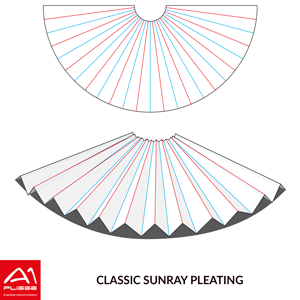

- Classic sunray pleating

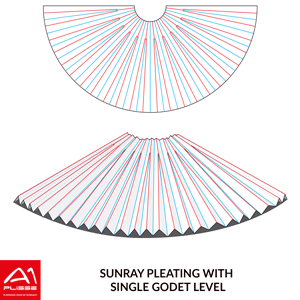

- Sunray pleating with godets

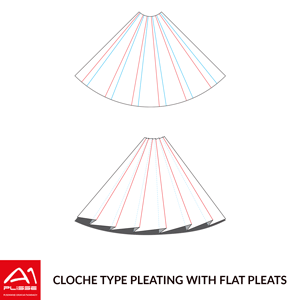

- Cloche type pleating with flat pleats

Classic sunray pleating

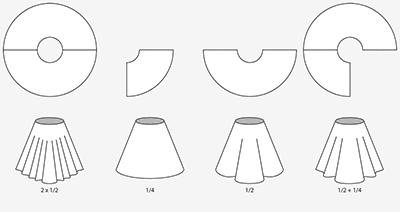

The basic version of sunray pleating - most often performed on patterns that are a segment of a circle (usually 1/2 circle, less often 1/4 circle). It is also possible to pleat patterns of a different shape, e.g. for sleeves or other inserts. In this type of pleating, the height of the pleat changes from very small at the upper edge of e.g. a skirt, and increases towards the bottom. Usually, 42 pleats (shorter skirts), 54 pleats (longer) and 60 pleats (very long) are used on 1/2 circle patterns, but we can make pleating templates with any number of pleats. Making a skirt or dress from one 1/2 circle element will not always be sufficient and visually a much better effect will be obtained by combining e.g. 2 1/2 circle cut-outs, or adding another 1/4 circle element to them, as with each additional element the visual volume of the skirt increases. The height of the pleats at the bottom and top edges of the sole is determined by:

- At the top edge from the circumference of the skirt at the waist, the number of patterns used to construct the skirt, the number of pleats

- At the bottom edge from the length of the skirt, the number of patterns used to construct the skirt, and the number of pleats (the longer the skirt, the larger the pleat at the bottom edge)

Sunray pleating with godets

Godets are an extension of the classic sunray pleating concept by adding additional, smaller pleats between the normal sunray pleats. Most often, one additional 'level' of pleats is added - this variant is called a single godet. However, we also make so-called double godets, where in addition to adding the first 'level' we add one more, slightly smaller. Adding this level increases the number of pleats, and consequently reduces the height of the pleat at the lower edge of the sunray skirt.

Templates for pleating godets are slightly more complex due to the above-mentioned addition of additional 'levels' of pleats. For this reason, most godet forms cover a smaller range of the circle and it is possible to pleat 1/4 circle patterns in this variant, some variants can be pleated using 1/2 circle patterns.

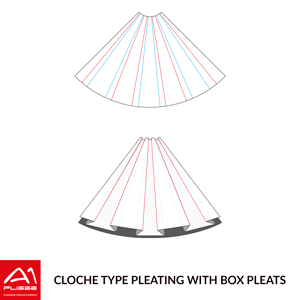

Cloche type pleating with flat pleats

Cloche type pleating is a combination of the shape of the sunray pleating pattern and the selected type of flat pleating. In contrast to the classic simple pleating (described in the "machine pleating" section), the use of a circle-shaped pattern allows for the height of the pleat to be changed starting at the upper edge of the element (the smallest pleat) and increasing towards the lower edge of the element. All cloche type pleats are done by hand and their parameters can be adjusted to your production needs. It is possible, for example, to use box pleats or repeat pleats and box pleats in a selected configuration. Cloche type pleating require a slightly different fixing process and due to technical limitations, only 1/4 circle patterns can be pleated in this variant.

Preparing the pattern

In addition to preparing the right mould, choosing the variant and the number of pleats in sunray pleating, another aspect is also important - the proper preparation of the pattern. For your convenience, we provide templates that allow for the correct preparation of the pattern. If you would like to start producing garments, that would utilize sunray type pleating, please contact us - based on your requirements, we will advise you on what to pay attention to and send you a template appropriate for a given case, we will also advise you on how to prepare the pattern, e.g. to leave space for later sewing, finish the edges or determine the radius of the cut for the selected waist circumference.

Edge colouring

In cooperation with our printing department, we have introduced the possibility of obtaining colored edges for classic sunray pleating, which allows to emphasize the beauty of finely pleated material. It is possible to dye the edges in solid colors (e.g. black, as in the photo next to it), tonal transitions or using patterns. It is also possible to dye only part of the length of the edges of the pleats (e.g. 20 cm from the top edge of the skirt).

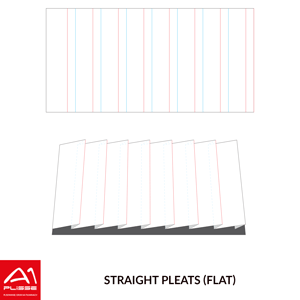

Flat pleats

Simple types of pleating are usually done by machine. Sometimes, however, we also carry out projects where the pleated material requires a little more attention. In such cases, the best solution is hand pleating. E.g. in the case of non-standard materials (e.g. with a higher material weight or requiring additional fixing processes) or non-standard patterns (e.g. oversized pleats, progressive pleats), we offer you the possibility of making patterns of flat pleats, box pleats, fancy pleats in a selected size. We carry out pleating on non-standard materials and/or in non-standard dimensions (e.g. curtains).

Fancy pleats

In addition to the typical types of hand pleating, we offer a wide range of decorative patterns, used as a whole or in smaller fragments as applications. For some of these special patterns we also offer fabric backing (with glued interlining), which increases the durability of the pattern and makes it easier to apply. Please visit our patterns tab for some of the photos of selected patterns.

Custom pleating

In addition to the above-mentioned service options, we also carry out custom orders. If you want to make a different type of pleating, try to make it on a different material (including atypical ones), combine different services or try to recreate pleating based on a photo or model - please contact us.