Knowledge Base

General

Every large production begins with individual tests, and some projects are so unique that they are produced as single pieces. The minimum order is one item—a material element, e.g., with your chosen dimensions, such as 20 cm x 20 cm or 1 m x 1.5 m.

Yes — it is possible to place an order entirely remotely — by phone, email, or even only by sending a package with attached order details.

Yes, you can request any of these services for just one item.

Pleating

The pleating process consists of two stages — the first is arranging the material into the chosen pattern, and the second is setting this arrangement using high temperature and pressure. Any material — synthetic fibers, artificial (e.g. viscose), or natural (e.g. cotton) - can be arranged, but setting the pleats is only possible with synthetic fibers and wool.

- In synthetic materials, the high temperature melts the fibers slightly; as they cool, the material "remembers" the folds.

- With wool, steam can be used in addition to temperature, allowing wool to retain the pattern.

- Other materials are resistant to heat and steam, so to maintain pleats in e.g. cotton shirts, additional securing is necessary — usually by sewing each pleat. Otherwise, pleated items will eventually return to their flat, original form.

Pleating (creating folds) is possible, but will not be permanent. Natural fibers resist heat, so with environmental temperature, humidity, and pressure during wearing, pleats "iron out" back to flat. To maintain pleats, extra securing such as stitching of each fold is needed. Some chemical treatments can also make fabrics — like silk — respond to heat and fix the pattern, but such treatments alter the fabric's properties. This essentially turns silk into something more like polyester (due to added chemical treatment) and in such case it is easier to just use polyester directly.

Several tests can be performed:

- If you suspect polyester or other synthetics—create a fold on a small piece and iron it (temperature: between level 2 and 3 on an iron). If you get a sharp crease that survives delicate washing, pleating is probably possible.

- For wool—make a fold and use a steam iron. If the crease is sharp, durable pleating is likely.

- Alternatively, burn a small, secured piece (e.g., 2.5 cm x 2.5 cm) and observe:

- Wool: Smells like burning hair, burns slowly, goes out when removed from flame, edge becomes crumbly.

- Silk: Burns similarly to wool, leaves small, brittle balls that turn to ash.

- Cotton: Burns even after removing the flame, smells like burning paper; the burnt part doesn’t crumble as easily.

- Polyester: Burns and melts slowly; smells chemical; edge is black and hard, not crumbly.

- Nylon: Burns like polyester, but the edge is lighter grey.

All material tests — especially those involving open flames or chemicals—should be carried out only by trained professionals in a controlled, safe environment. Working with fire and chemical substances poses risks to your health and safety. Please do not attempt these procedures without proper training, equipment, and safety measures.

Sew each pleat; you can also reinforce pleated fabric with special glue interlining. There are patterns in our offer where interlining is also advised, due to the direction of the pleats - the interlining keeps patterns stable and prevents stretching of the material.

Polyester pleated fabrics may be machine-washed using a delicate program. They should be dried hung up (not in a tumble dryer). Ironing may flatten the pleats or introduce new creases, so it should be used with great caution or ideally avoided entirely in pleated areas.

Fabrics have two threads: the weft runs across the width, and the warp runs parallel to the side edges. The fabric always "remembers" the arrangement of weft versus warp. If the warp and weft are not correctly aligned (e.g., the fabric is stretched askew), one edge of the skirt may drift sideways, as the weft strives to straighten itself.

The simplest way is to tear a piece of fabric from one selvage to the other. The tear line should be at a right angle to the selvage. If there is no right angle, the fabric is skewed.

You may send your materials (photos/stencil scans) to our email or send the models/stencils to our company address. After analyzing the materials provided, we shall inform you about the type of pleating, suitable elements for the process, and provide a price quotation.

Prices depend on the chosen pattern, parameters, and the material in which the service is to be performed. Simple machine-made pleating costs about 15 EUR (64 PLN) per running meter, whereas hand pleating — for example, a simple sunray half-circle skirt — starts at approximately three times this amount. For a precise quotation for your project or model, please contact us.

Machine Pleating

In machine pleating, fabric is placed between two layers of special paper and fed into the machine through special knives. The knives pre-arrange the paper and fabric, which are then fed into the fixation section, where heated rollers fix the pattern under pressure. The fixation time (temperature and pressure) is adjustable and depends on the pattern and material. After heating, the paper and material move to the cooling stage, where the pattern is set.

Pleating from the roll is possible for selected patterns. Any imperfections in the fabric — if present — will have a greater impact on the appearance of pleating, than when pleating individual elements. For instance, if the material on the roll is stretched on one side, errors may appear in that area. If the threads are skewed, the pleats will still be made perpendicular to the selvage. But since the weft line is not perpendicular to the selvedge (due to material being stretched) the pleats will not be parallel to the weft line, causing the bottom of a skirt to drift and hem edges to curve.

Occasionally, we encounter fabrics with different fiber compositions in warp and weft. Some are suitable for pleating only parallel to the selvage. Attempting to pleat such materials perpendicularly to the selvage (from the roll) does not result in permanent pleating.

For most patterns, the maximum width is 150 cm. We also have machines for narrower materials. For selected patterns it is also possible to pleat wider material (standing pleats up to 240 cm wide).

This is possible only for selected patterns and materials, and exclusively for items without buttons, zippers, or similar accessories.

During pleating, the fabric is folded so that what was one layer now becomes three (a pleat). If, for example, a blouse has double or triple layers, pleating in those areas will result in six or even nine layers. Such significant differences in thickness can cause defects in the pattern at these junctions.

Yes, our offer includes pleating patterns with unpleated sections—for example, flat pleats, small accordion pleats, or "ruffle" pleating. Combining different types of folds is also possible for certain designs, but the entire material must be pleated by one method and then by the second chosen method; it is not possible to pleat half the item with one method and the other half with another.

Hand Pleating (Sunray)

Sunray pleating is mainly used for skirts/dresses and is most often done on semicircular cutouts, featuring a small pleat at the top edge which enlarges toward the hem.

Sunray pleating can be performed on almost any material. Durable pleating is only possible on wool, polyester, and other synthetic fabrics.

Although pleating is possible on cotton, viscose, or silk, it will not be permanent, and after some time the fabric will return to its original flat form. To maintain pleats, extra securing such as stitching of each fold is needed.

First, determine the number of pieces (e.g., 1 or 2) and their shapes (e.g., half-circle, quarter-circle) required for the skirt. Using templates provided by our company, calculate the cutting parameters, considering waist circumference, length, and allowances for sewing elements together.

We usually pleat pieces that are segments of a circle—half or quarter circles. Sometimes, two half-circle elements are pleated and sewn together to form a full circle skirt. Cutting a sunray pattern from a full circle often requires a large piece of fabric (about 2.5 m in diameter), usually exceeding standard material width. A half-circle cut yields a piece of 1.25 m by 2.5 m, which typically fits on standard material width.

Usually not practical due to fabric size limits. For very short items (like sleeves), nearly full circle pleating is possible.

Allow approximately 1 cm extra material at the edge so that all pleats are even after sewing.

The basic model is a half-circle piece with a curve of 10–30 cm, a length of 60 cm, and 42 pleats per half-circle. Other common quantities are 48, 54, and 60 pleats. Custom pleat numbers and shapes are possible.

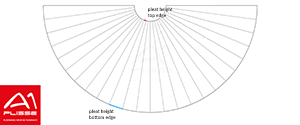

Pleat height at top/bottom depends on sunray pattern parameters: top curve radius, and number of pleats determine top height; radius, pleat count, and length determine bottom height.

To get larger pleats at the top you can either decrease the number of pleats (resulting in longer segments) or increase the radius of the curve (making the edge longer and the segments longer after division). Extending the curve will also increase the waist circumference.

To get larger pleats at the top you can either decrease the number of pleats (resulting in longer segments) or increase the radius of the curve (making the edge longer and the segments longer after division). Extending the curve will also increase the waist circumference.

Crashing / Crushing

The crashing/crushing process can be split into two stages - first we arrange the material in a particular pattern, then we fix the pattern with high temperature and pressure. Any synthetic/artificial/natural fiber can be crushed/crashed, but only synthetics can be set:In synthetics the heat melts the fibers which then are able to "remember" the pattern. Other fibers resist temperature/steam, so durable crashing/crushing of e.g. cotton requires reinforcement (glue, stitching, backing layer). Otherwise the crashed/crushed material will flatten itself after some time.

Yes, for one pattern — irregular crash/crush. The item should not include buttons/zippers, as these can get damaged during process or damage the machines.

For most crashing/crushing patterns the degree of density can be customized.

It depends on pattern and crashing/crushing density:"Shattered glass" pattern: up to 1.5m x 1m. Larger items = less density. If a backing layer is to be applied after crinkling, the maximum size is 1m x 0.7m. Type "5" crashing/crushing - max width = 1.5m. Usually we work with 1.5m x 1.5m panels, it is also possible to crash/crush material from roll in lengths around 15-20 m per piece.

Yes, for type "5" - the material is cut into 15m-20m sections during the process.

The backing layer should be applied directly after crashing/crushing - max glued panel size is 1m x 0.7m. Most crashing/crushing patterns do not require backing layer except for situations where material weight would stretch and flatten the crashed/crushed material when used. In such cases it is recommended to apply backing layer.

Embossing

- (recessed) embossing — polyester or similar artificial fiber materials.

- (using a special polymer) — possible on many materials, both natural (e.g. cotton) and synthetic (e.g. polyester).

To check suitability, plase send a piece of target material with planned embossing type marked.

Yes, both types of embossing are permanent if done on proper materials with correct parameters. Embossed material may be washed using delicate programme, but cannot be ironed, as high temperature may damage the embossing.

It is possible for both types of embossing (2d and 3d), but only on front and back of items.

Send the design as a 1:1 scale vector file. We will check if the requirements for the design are met and let you know if any modifications are needed. If the design is in line with our specification, we will provide quote for dies/molds (2d: die; 3d: set of die and counter-die). If possible, please send a sample of the target material/item.

Yes — both types of embossing support custom designs.

One item — you can order just a die or die+counter-die, and then emboss one item.

Maximum embossing size depends on embossing type and whether the embossing is to be made on a pattern or ready item.2D (recessed): on patterns — max size is 40x50cm (small die), up to 60x90cm (large die with more design constraints and possible only for specific designs). On ready items — max size is 30x30cm. 3D: on patterns or ready items — max 400 cm².

No — it is not possible to emboss on material directly from roll.

Printing

Sublimation printing is possible on polyester fabrics and materials with a high content of polyester or other synthetic fibers (such as polyamide, elastane).

Yes, printing can be carried out on both lightweight (e.g., chiffon) and heavyweight materials (e.g., barbie, sports knits).

Yes, the material should be resistant to high temperatures—sublimation involves heating to approximately 190–200°C. Fabrics not properly stabilized during production may shrink when exposed to these temperatures.

No, sublimation inks bond only to synthetic fibers. Printing is not possible on natural-fiber-only fabrics.

Printing is possible on blends (e.g., polycotton), but the print will only attach to the synthetic fibers—for example, if the content is 50% polyester, the print will be half as intense. The remaining cotton fibers will not take the print.

Files should be prepared in raster format (TIFF), sRGB color space, with a minimum resolution of 150 dpi and at the target size in centimeters.

Yes, but remember that with sublimation printing, only lighter areas of the material can be darkened or colored. White cannot be printed on black material; the result will be invisible due to the limitations of the technology.

Yes, we print on patterns — including blouses and skirts for sunray pleating. Please add approximately 5 cm bleed to each side in your design files.

No, despite technical possibilities, the quality cannot be guaranteed on the entire surface. Sublimation printing is sensitive to fabric thickness changes and cannot penetrate deep into fibers. As a result, errors—the most common being unfinished print under seams or hoods, blurred print, or areas missed by the ink—may occur.